产品介绍

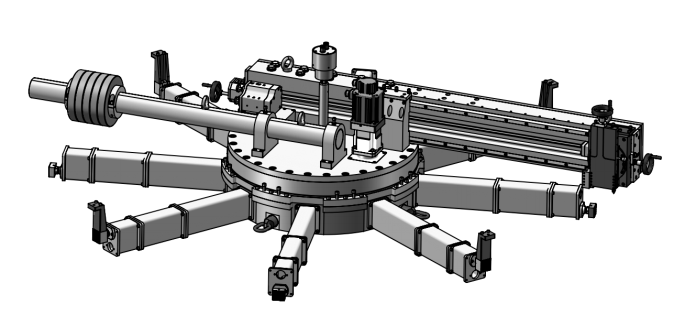

WF-3000法兰端面加工机床是一种轻便、高效的产品。机器采用内部夹紧方式,固定在管道或法兰中间。它可以加工内孔,外圆,法兰的各种形式的密封面 (RF,RTJ等)。整机采用模块化设计,易于安装和拆卸,配有预紧制动系统,能够间歇切割,工作方向无限,生产率高,噪音低。广泛应用于铸铁、合金结构钢、不锈钢等各种金属材料的法兰密封面维修、法兰表面修复和加工。

产品主要应用于核电、造船、石油化工、海洋石油、工程机械、冶金等多个领域。我们的目标不仅是为各个领域的用户提供专业的安装和维护设备,更希望在行业内推广这种先进的维护理念,分享丰富的行业应用经验,专业提供安装、维护等工艺技术的创新解决方案。

便携式法兰车床性能:

参数:

| 法兰端面加工机 | |

| 机器型号 | |

|

加工外径 (mm) |

1150-3000 |

|

安装范围 (mm) |

1150 -- 2800 |

|

刀具行程 (mm) |

100毫米 |

| 刀盘旋转角度 |

± 360 ° |

| 刀盘速度 |

1-20r/微型无级调节 |

| 驱动方法 | 伺服电机 (松下) |

| 电机功率 |

AC380V 50HZ 5KW |

| 加工平整度 |

≤ 0.1毫米 |

| 加工表面粗糙度 |

Ra3.2-Ra6.3 |

| 单次切削深度 |

<1毫米 |

联系我们

深圳市科德机械设备有限公司

地址: 深圳市龙华区洋金工业园c座

电话: 86 19166278852 (外国手机号码)

18665878998 /13417343491 (国内手机号码)

传真: 86-0755-82598826

邮箱: pokouji@139.com (国内邮箱)

Kedesmachinery@outlook.com (外国邮件)

-

ꁸ Top

-

ꂅ 86+19166278852

-

ꀥ QR code