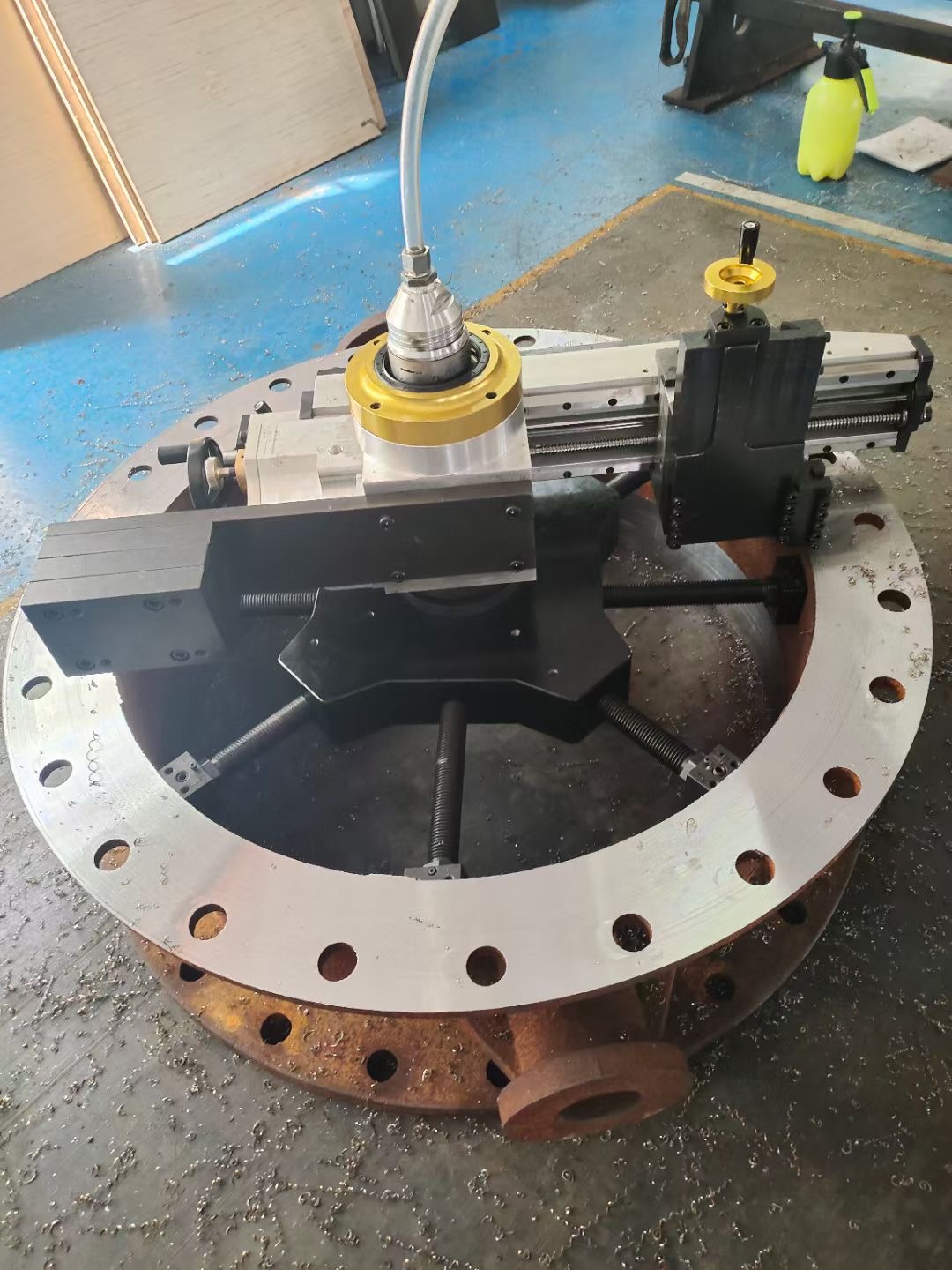

Equipment Introduction:

Flange end face processing machine for flange face,water line,seal groove processing using the latest linear and ball screw technology,The machine adopts the method of clamping inside,fixed in the middle of the pipe or flange,Used to process the inner hole, outer circle and various forms of sealing surface of flange(RF,RTJ, etc.).

1.Main slewing mechanism

The use of customized high-precision main slewing bearings, strong bearing capacity, smooth turning process, to ensure machining accuracy. The lower part of the chassis has an adjustment mechanism and is equipped with an adjustable balance weight.

2.knife arm

adopts a high-strength aviation aluminum and steel plate composite structure to ensure the strength while reducing the weight of the cutter arm, strong bearing capacity, high precision, and ensuring processing accuracy. The knife arm can move according to the rotation space and processing range.

3.Main slewing control system

is controlled by a remote control box, with start, stop and reverse inching functions, and the speed is stepless speed regulation.

4.Flange plane machining(Horizontal direction)

Flange plane processing feed is automatic feed, the processing form is continuous spiral, with three gears of forward, neutral and reverse, and the feed speed is equipped6stalls, can process water lines. Manual rapid feed is available in neutral gear.

5.tool holder

tool holder can360 °rotation, can process chamfers, sealing grooves, etc.

Equipment Features:

- Modular design,easy to operate,Easy to install and remove.

- preload brake system can make the inter-song cut flat.

- horizontal, vertical, inverted installation can be, good stability.

- Three power systems for selection:Same service motor, pneumatic motor and hydraulic motor

full range of flange processing machine

1. Main slewing mechanism

The use of customized high-precision main slewing bearings, strong carrying capacity, smooth turning process, to ensure machining accurac